3D printing

3D printing

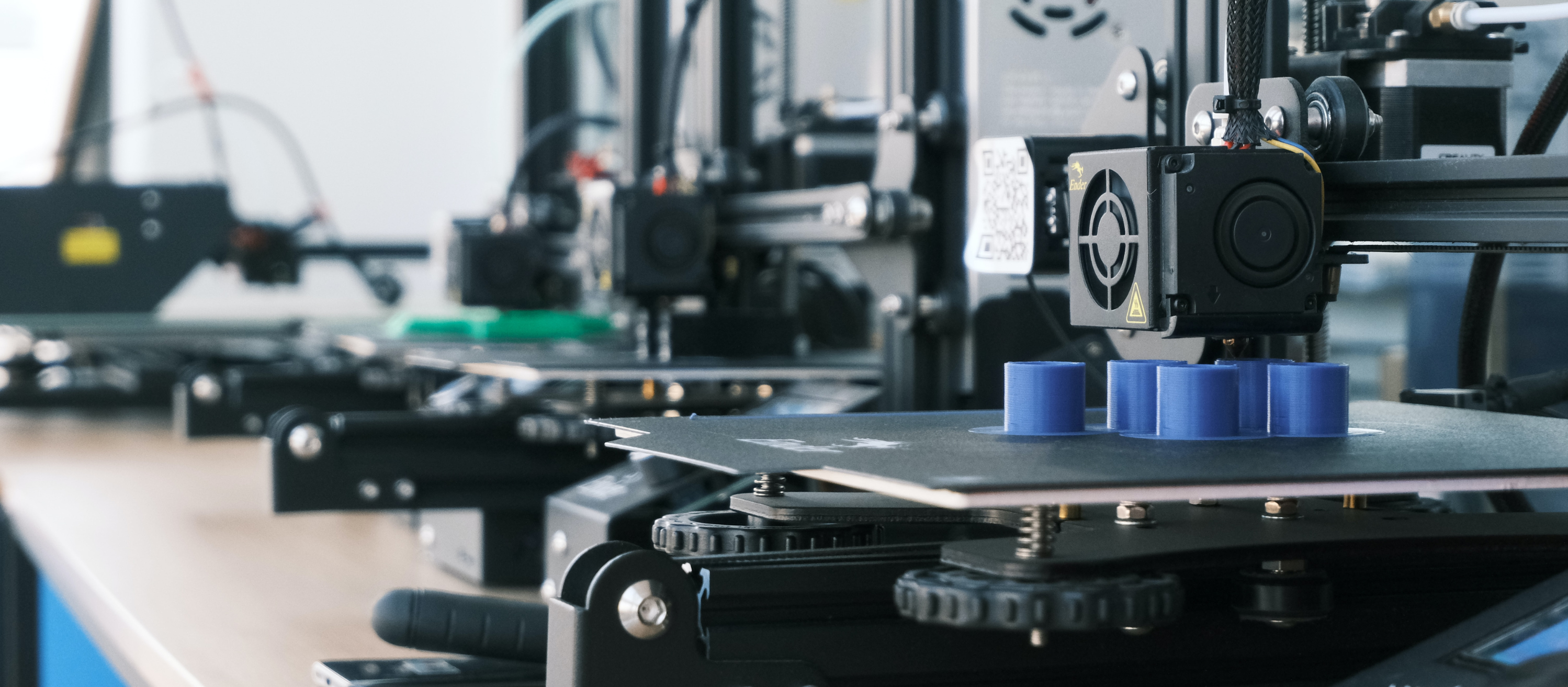

3D printing revolutionizes the way hardware product-based startups prototype and produce parts. Using cutting-edge additive manufacturing technology, we transform digital designs into tangible objects with incredible speed and precision. Whether you need functional prototypes or end-use parts, 3D printing offers rapid turnaround times, cost-effective production, and design flexibility. By leveraging a range of materials and printing technologies, startups can quickly iterate, test, and validate their product designs, accelerating the time-to-market and reducing development risks.

Tab

- Fused Deposition

- Stereolithography

- Selective Laser

Fused Deposition Modeling (FDM) is a common 3D printing technique that builds parts layer by layer by extruding thermoplastic materials. It is widely used for rapid prototyping, functional testing, and low-volume production of consumer products, automotive parts, and medical devices.

Stereolithography (SLA) uses a UV laser to cure liquid resin layer by layer, creating precise and high-resolution parts. It is suitable for producing detailed prototypes, concept models, and intricate components used in automotive, aerospace, and consumer electronics industries.

Selective Laser Sintering (SLS) employs a high-powered laser to selectively fuse powdered materials, such as nylon or metal, to create durable and functional parts. It finds applications in manufacturing end-use parts, tooling, and complex geometries that require high strength and heat resistance, such as in aerospace, automotive, and industrial equipment

Fused Deposition Modeling (FDM) is a common 3D printing technique that builds parts layer by layer by extruding thermoplastic materials. It is widely used for rapid prototyping, functional testing, and low-volume production of consumer products, automotive parts, and medical devices.

Stereolithography (SLA) uses a UV laser to cure liquid resin layer by layer, creating precise and high-resolution parts. It is suitable for producing detailed prototypes, concept models, and intricate components used in automotive, aerospace, and consumer electronics industries.

Selective Laser Sintering (SLS) employs a high-powered laser to selectively fuse powdered materials, such as nylon or metal, to create durable and functional parts. It finds applications in manufacturing end-use parts, tooling, and complex geometries that require high strength and heat resistance, such as in aerospace, automotive, and industrial equipment

FAQ

- We offer a wide range of materials for 3D printing, including ABS, PLA, Nylon, PETG, and more. Each material has unique properties suitable for different applications.

- 3D printing is utilized in various industries, leading to the production of diverse parts, including:

- Aerospace: Manufacturing lightweight and complex aircraft components, such as brackets, ducts, and interior structures.

- Automotive: Prototyping vehicle parts, such as custom interior panels, intake manifolds, and intricate engine components.

- Medical: Creating patient-specific implants, surgical models, dental aligners, and prosthetic limbs.

- Consumer Products: Producing customized phone cases, jewelry, fashion accessories, and home decor items.

- Robotics: Manufacturing robot grippers, end-effectors, and intricate mechanical parts.

- Architecture: Constructing detailed architectural models and prototypes.

- Yes, our advanced 3D printing technologies can achieve high levels of detail and intricate designs. We employ precision printing techniques to ensure the accuracy and quality of the final prints.

- The turnaround time for 3D printing depends on factors such as the complexity of the design, the size of the part, and the chosen material. We strive to deliver prints within 1 business day.

- Yes, we offer post-processing services such as sanding, polishing, painting, and assembly to provide a finished look to 3D printed parts and meet specific requirements.