Exploring Additive Manufacturing for Startup Success

- Shashank

- Manufacturing , Outsourcing

- 22 May, 2023

In today’s competitive business landscape, startups are constantly seeking innovative ways to gain a competitive edge. One such technology that holds great promise for startups is additive manufacturing. Also known as 3D printing, additive manufacturing offers a range of benefits and applications that can revolutionize the way startups operate. In this article, we will explore the benefits, applications, and key considerations of additive manufacturing for startup success. So, let’s dive in and unlock the potential of additive manufacturing in your startup!

Table of Contents

Open Table of Contents

-

4. Key Considerations for Implementing Additive Manufacturing in Startups

-

5. Frequently Asked Questions (FAQs)

- 5.1 How can additive manufacturing benefit my startup?

- 5.2 What are the limitations of additive manufacturing?

- 5.3 Is additive manufacturing suitable for mass production?

- 5.4 How can startups ensure the quality of additive manufacturing products?

- 5.5 Can additive manufacturing be used for medical applications?

- 5.6 What are the future prospects of additive manufacturing?

1. Understanding Additive Manufacturing

1.1 What is Additive Manufacturing?

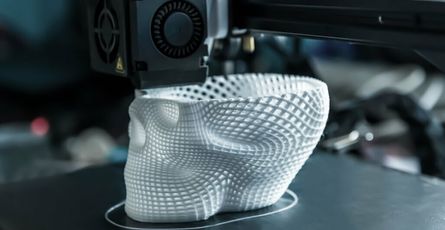

Additive manufacturing refers to the process of creating three-dimensional objects by adding layers of material on top of each other. Unlike traditional manufacturing techniques that involve subtracting material from a solid block, additive manufacturing builds objects layer by layer. This process offers greater design freedom and flexibility, allowing for the creation of complex geometries that would be challenging or impossible to achieve with conventional manufacturing methods.

1.2 How Does Additive Manufacturing Work?

Additive manufacturing works by using computer-aided design (CAD) software to create a digital model of the object to be printed. The CAD file is then sent to a 3D printer, which interprets the design and builds the object layer by layer. The printer deposits material, such as plastic, metal, or even biological tissue, according to the specifications of the digital model. This layer-by-layer approach enables the creation of intricate and highly customized objects.

1.3 The History of Additive Manufacturing

Additive manufacturing has its roots in the 1980s when the first commercial 3D printing technologies were developed. Over the years, the technology has evolved and become more accessible, leading to its widespread adoption across industries. Today, additive manufacturing is used in various sectors, including aerospace, automotive, healthcare, and consumer products, among others.

1.4 Additive Manufacturing vs. Traditional Manufacturing Techniques

Additive manufacturing differs from traditional manufacturing techniques, such as injection molding or CNC machining, in several ways. While traditional techniques are subtractive, meaning they remove material to create the desired shape, additive manufacturing is additive, building objects layer by layer. This fundamental difference gives additive manufacturing its unique advantages, such as increased design freedom, reduced material waste, and faster production times for complex geometries.

2. Benefits of Additive Manufacturing for Startups

2.1 Rapid Prototyping and Iteration

One of the key advantages of additive manufacturing for startups is its ability to facilitate rapid prototyping and iteration. Startups often operate in a fast-paced environment where time-to-market is crucial. With additive manufacturing, entrepreneurs can quickly turn their ideas into physical prototypes, allowing them to test and refine their designs without the need for expensive and time-consuming tooling.

2.2 Cost Savings and Efficiency

Additive manufacturing can also result in significant cost savings for startups. Traditional manufacturing methods often require expensive molds, dies, or tooling, which can be a barrier for cash-strapped startups. In contrast, additive manufacturing eliminates the need for these upfront costs, making it more accessible to entrepreneurs with limited resources. Additionally, the ability to consolidate multiple components into a single 3D-printed part can streamline production processes and improve overall efficiency.

2.3 Design Flexibility and Complexity

Another benefit of additive manufacturing is the design flexibility it offers. Startups can leverage this technology to create complex geometries, intricate structures, and organic shapes that would be challenging or impossible to achieve with traditional manufacturing techniques. This design freedom enables startups to differentiate their products and create innovative solutions that meet the unique needs of their target markets.

2.4 Customization and Personalization

In today’s consumer-centric world, customization and personalization are increasingly important. Additive manufacturing allows startups to create highly customized products tailored to individual customer preferences. Whether it’s personalized jewelry, customized footwear, or bespoke medical devices, startups can leverage additive manufacturing to offer unique and tailored solutions that resonate with their customers.

2.5 Reduced Time-to-Market

Time-to-market is critical for startups aiming to seize market opportunities and stay ahead of the competition. Additive manufacturing can significantly reduce the time it takes to bring a product from concept to market. By eliminating the need for complex tooling and enabling rapid prototyping, startups can iterate on their designs faster and get their products in the hands of customers sooner, gaining a competitive edge in the process.

3. Applications of Additive Manufacturing in Startups

3.1 Product Development and Innovation

Additive manufacturing plays a vital role in product development and innovation for startups. It enables entrepreneurs to quickly produce functional prototypes, test their ideas, and gather feedback from users and investors. By incorporating additive manufacturing into their product development processes, startups can accelerate innovation cycles, reduce development costs, and increase their chances of creating successful products.

3.2 Supply Chain Optimization

Startups often face supply chain challenges, especially when dealing with limited resources or complex product requirements. Additive manufacturing can help startups optimize their supply chains by reducing dependencies on external suppliers, streamlining inventory management, and enabling on-demand production. With additive manufacturing, startups can manufacture components and products in-house, reducing lead times, minimizing transportation costs, and improving overall supply chain efficiency.

3.3 On-Demand Manufacturing

Traditional manufacturing typically involves producing goods in large batches, which can result in excess inventory or stockouts. Additive manufacturing allows startups to embrace on-demand manufacturing, where products are manufactured in response to customer orders. This approach reduces inventory holding costs, eliminates the risk of obsolete stock, and enables startups to offer shorter lead times to their customers.

3.4 Spare Parts Production

For startups operating in industries that rely on equipment or machinery, the availability of spare parts is crucial. However, sourcing and stocking spare parts can be expensive and inefficient. Additive manufacturing offers startups the ability to produce spare parts on-demand, eliminating the need for large inventories and reducing downtime caused by equipment failures. This capability can significantly improve operational efficiency and customer satisfaction.

3.5 Customized Manufacturing Solutions

Startups often face unique manufacturing challenges that require tailored solutions. Additive manufacturing can provide startups with the flexibility to create custom jigs, fixtures, and tooling that meet their specific manufacturing needs. By leveraging additive manufacturing, startups can optimize their production processes, improve quality control, and overcome manufacturing constraints that traditional methods may not address effectively.

4. Key Considerations for Implementing Additive Manufacturing in Startups

4.1 Cost Analysis and Return on Investment (ROI)

While additive manufacturing offers numerous benefits, startups must carefully evaluate the costs associated with implementing and operating this technology. Factors such as equipment costs, material expenses, maintenance requirements, and training should be considered when conducting a cost analysis. Startups should also assess the potential return on investment (ROI) and determine if the benefits of additive manufacturing outweigh the initial investment and ongoing costs.

4.2 Material Selection and Compatibility

Choosing the right materials for additive manufacturing is crucial for achieving desired product characteristics and performance. Startups need to consider the properties of different materials, such as strength, flexibility, heat resistance, and compatibility with specific applications. Understanding the material limitations and ensuring compatibility with the printing process is essential to produce high-quality and functional parts.

4.3 Intellectual Property Protection

Startups should be mindful of intellectual property (IP) protection when utilizing additive manufacturing. The digital nature of additive manufacturing files makes them susceptible to unauthorized copying or distribution. Startups should implement appropriate security measures to safeguard their designs and consider legal protections, such as patents or copyrights, to defend their IP rights.

4.4 Quality Control and Certification

Maintaining quality control is vital for startups adopting additive manufacturing. Startups must establish rigorous quality assurance processes to ensure the consistency, accuracy, and reliability of printed parts. Additionally, for industries with regulatory requirements, startups should seek necessary certifications to comply with standards and regulations governing their products.

4.5 Equipment and Maintenance Requirements

Startups need to consider the equipment and maintenance requirements associated with additive manufacturing. Selecting the right 3D printer, software, and post-processing equipment is crucial for achieving desired outcomes. Additionally, startups should allocate resources for regular equipment maintenance, calibration, and operator training to ensure optimal performance and longevity.

5. Frequently Asked Questions (FAQs)

5.1 How can additive manufacturing benefit my startup?

Additive manufacturing can benefit your startup in several ways. It offers rapid prototyping and iteration capabilities, cost savings and efficiency, design flexibility, customization options, and reduced time-to-market. By leveraging additive manufacturing, you can accelerate innovation, optimize your supply chain, and create unique products that meet customer needs.

5.2 What are the limitations of additive manufacturing?

While additive manufacturing has many advantages, it also has some limitations. These include limited material options compared to traditional manufacturing, slower production speeds for large volumes, post-processing requirements for certain applications, and higher upfront costs for equipment and materials. However, as the technology advances, these limitations are continually being addressed.

5.3 Is additive manufacturing suitable for mass production?

Additive manufacturing is well-suited for producing small to medium quantities of highly customized products. However, it may not be the most efficient option for large-scale mass production due to the time and cost associated with printing individual parts. For mass production, a combination of additive manufacturing for customization and traditional manufacturing techniques for high volumes may be more appropriate.

5.4 How can startups ensure the quality of additive manufacturing products?

Startups can ensure the quality of additive manufacturing products by implementing robust quality control processes. This includes regular calibration and maintenance of equipment, material testing and selection, adherence to industry standards, and thorough inspection and testing of printed parts. Additionally, startups can leverage quality management systems and certifications to demonstrate their commitment to producing high-quality products.

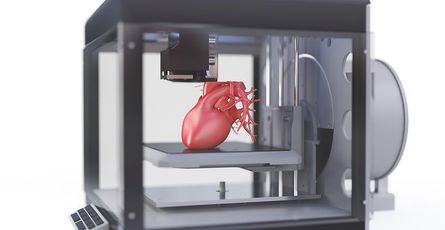

5.5 Can additive manufacturing be used for medical applications?

Yes, additive manufacturing has found significant applications in the medical field. It enables the production of patient-specific implants, prosthetics, surgical guides, and medical models. Additive manufacturing allows for complex geometries, customization, and rapid production, making it an ideal technology for advancing medical solutions.

5.6 What are the future prospects of additive manufacturing?

The future prospects of additive manufacturing are promising. As technology continues to evolve, we can expect improvements in speed, material options, and scale. Additive manufacturing is likely to become more integrated into existing manufacturing processes, leading to increased adoption across industries and the emergence of new applications.

Conclusion

In conclusion, additive manufacturing holds immense potential for startup success. By exploring and embracing additive manufacturing, startups can unlock a range of benefits, including rapid prototyping, cost savings, design flexibility, customization, and reduced time-to-market. However, careful consideration of key factors, such as cost analysis, material selection, IP protection, quality control, and equipment requirements, is essential for successful implementation. With the right approach and understanding of additive manufacturing, startups can harness its power to drive innovation, streamline operations, and gain a competitive edge in the marketplace.